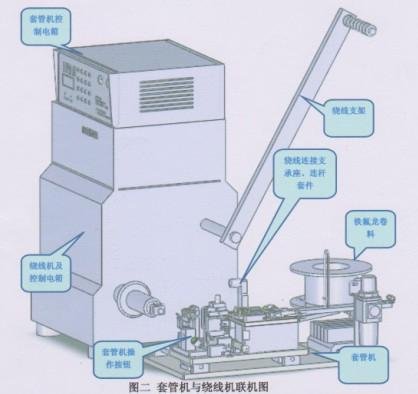

The main configuration of the automatic casing machine for the Hui is introduced

Automatic wearing machine casing in the existing CNC winding machine equipped with wear sleeve mechanism for production and the comparison of the existing mode of production, institutions will use around the line personnel will copper head wrapped around this time in the pin and the upper and lower material automatic pipe cut to the specified length and the copper head automatic wear casing stand-by, artificial guide pull wire hanging foot copper thread had been wearing casing, only need a hand in the cable and location (the action time is less than 0.5s) casing can be directly using the. In the purchase of my automatic wear casing machine, at the same time, I will be the Secretary for the installation and commissioning, the test department after passing the test to ship, but also to provide the installation of video education, quality assurance. The following detailed HY-R20 automatic casing machine configuration features.

The 1 casing length can be set arbitrarily, the terminal can be selected.

2 this machine can be divided into two feeding tube. This machine can be set up in a tube, and can also be set up in two tubes...

3 this machine is suitable for any brand burning machine, the direct installation can use. Very convenient.

4 function is very powerful: automatic feeding casing, automatic cut off, automatic wear casing, optimize the production of the staff action.

5 lead automatically send out, automatically finish wearing sleeve operation.

The 6 Teflon sleeve automatic wear casing machine for 18L~30L, 19L-14L.

This automatic threading machine is suitable for line diameter 0.1-1.0mm or 0.8-1.7mm, and the amount of the product is equal to the 1-60 shares of the following products

Automatic wear process: wear casing casing casing: the principle of multi strand diameters greater than the diameter of +0.15mm. A rated power: 220V.