Recently, I received a lot of Division EE10 ferrite core transformer manufacturers, the question I am Secretary of HY-B08 automatic assembly machine core ability for them to work EE10 ferrite cores by our engineering department to see after the customer's product to determine the Division I Cixi assembly machine can EE10 ferrite core encapsulated into automatic assembly work, and that the more Deng Hui workers today to tell you about the characteristics of soft ferrite cores:

1 ferrite core material

Because of its characteristics ferrite in the switching power supply application is very extensive. Its advantages are high resistivity, ac eddy current loss is small, inexpensive, easily processed into various shapes cores. The disadvantage is a low operating magnetic flux density, permeability is not high, a large magnetostriction, are sensitive to temperature changes. Choose what kind of soft ferrite materials more fully meet the design requirements of the high-frequency transformer, careful consideration, we can make the design out of the transformer to achieve ideal performance and low cost.

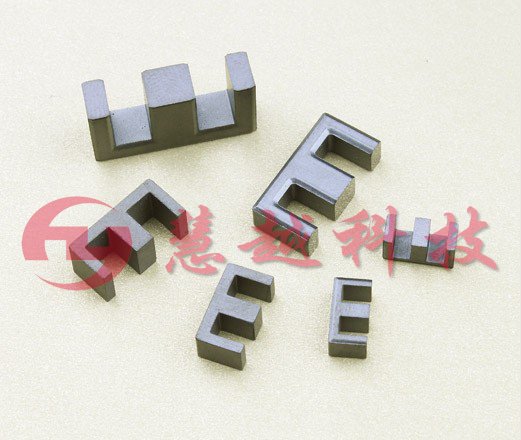

2 ferrite core structure

When selecting core structure factor to consider are: to reduce magnetic flux leakage and leakage inductance, increasing the coil cooling area is conducive to shield coil winding easy and convenient assembly wiring.

Magnetic flux leakage and leakage inductance is directly related to the core structure. If the core does not require an air gap, the possible use of a closed ring and box type structure core.

3 ferrite core parameters: core parameter design, paying particular attention to the work of the magnetic flux density is not only restricted by the magnetization curve, but also to limit the loss of the affected, but also the work related to power transmission. When the change in magnetic flux in one direction: ΔB = Bs-Br, well received by the saturation flux density limit, but more important is that the loss limit (loss caused by temperature, the temperature rise would affect the magnetic flux density). Operating flux density Bm = 0.6 ~ 0.7ΔB

Gapping can reduce Br, in order to increase the value of the magnetic flux density ΔB, after gapping, excitation current has increased, but it can reduce the volume of the core. For bi-directional flux in terms of work: maximum operating flux density Bm, ΔB = 2Bm. When the two sides to change the operating mode, but also pay attention to positive and negative changes due to various causes excitation of the volt-second area is not equal, and DC bias problems. You can add a small gap in the core, or in circuit design plus DC blocking capacitors.

More high-frequency transformer core assembly encapsulation technology problems can be more readily Hui core assembly machines Frequently Asked Questions area