Some factors leading to the failure of automatic casing machine

The operation steps of the automatic casing machine after starting:

Clean - check (double pressure waste block inside and clean) - Exit - operation

Abnormal in work:

Exit - - - - - - check (as) - Exit - run

Teflon tube plugging fault

1 to send a large needle selection, inspection and selection of the right to send a needle

2 double pressure block pre pressure gap is too small or too large, check and debug the preloading slot (Teflon sleeve cannot from the side out)

3 double press block close open is not flexible, in the side of the side of the WD-40 anti rust oil, and use the dust gun to clean up

Automatic threading of casing failure

1 wire guide wire selection is too large, check the wire guide is reasonable, and the replacement of a model of the line

2 wire guide wire selection is too small (copper forced by) to increase a model

3 wire wheel wear, replace the new wheels, and adjust the tension force of the small L arm

4 Teflon tube incision is not round, the replacement pipe cutting blade

5 wire feeding guide needle and double pressure block distance is too large (two of the distance 0.1mm, please use our confirmation to gauge the distance)

Automatic casing machine other failure

1 motor vibration does not run: check the data line link or directly replace the control box.

2 out of the line is not within the line of the line: the length of the extension cord, wire wheel wear, replace the new wheel. Check whether the clip line into the line of action is slow, if the slow change of the control clip line into the solenoid valve.

3 noise in the operating process of the muffler, check the solenoid valve, the replacement tangent knife cylinder

4 other parts of the leak, check the stainless steel joints are loose or replacement of stainless steel joints

Automatic threading machine for attention

1 select the right sleeve guide and copper wire guide

2 clear material, must check and clean the double pressure of the waste and confirm the double press block can be closed after the launch of the operation

3 air pressure is greater than 5.5 kg.

4 adjustable double pressure block suitable for preloading height (pressure regulating block with different height according to different Teflon sleeve)

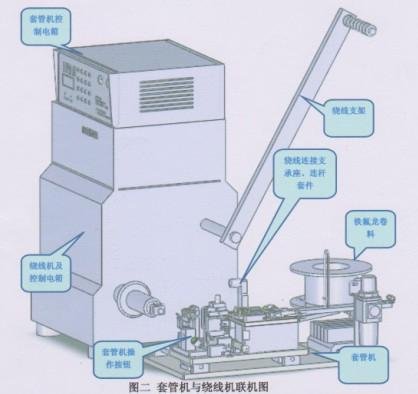

HY-R20 automatic casing machine: